Cut to length machine is a commonly used automated equipment in the metal processing industry, mainly used to shear various types of metal sheets (such as cold-rolled steel, hot-rolled steel, stainless steel, aluminum, copper, etc.) into the required fixed-length sheets.

Its main function is to cut the uncoiled metal sheet according to the size requirements set by the customer through precise shearing operations. Cut to length machines are widely used in various manufacturing industries, especially in vehicle manufacturing, household appliances, steel structure buildings, machine manufacturing, stainless steel kitchen supplies and other industries.

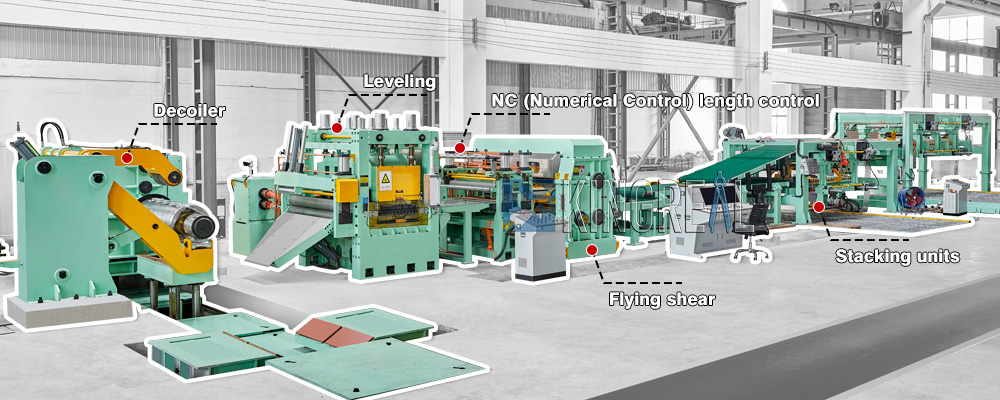

Cut to length lines usually consist of multiple functional modules, including decoilers, leveling machines, cut to length machines, material dividing devices and stacking machines. Its working principle is to process metal sheets from coiled state into flat sheets that meet standards through a series of processes. In this process, the metal sheet is fed into the cut to length line and accurately cut by the upper and lower shearing blades. The running speed of the blade is controlled by electrical components to ensure accuracy and consistency during the shearing process.

The machine can not only handle a variety of metal materials, but also adjust the cutting thickness and size according to different needs. Due to its efficient automated operation, cut to length lines are widely used in large-scale production environments, helping customers improve production efficiency, reduce labor costs, and ensure high precision and quality of products.

KINGREAL STEEL SLITTER has more than 20 years of rich experience in cut to length machine manufacturing. As a professional enterprise integrating R&D, production and sales, KINGREAL STEEL SLITTER is committed to providing customers with customized shearing line solutions to meet the needs of different industries and applications.

KINGREAL STEEL SLITTER's engineering team has a deep understanding of customer needs, and after full communication, they tailor the best solutions for customers according to specific production requirements to ensure that each cut to length line can perfectly adapt to the customer's production environment and needs.

KINGREAL STEEL SLITTER attaches great importance to customer service. From pre-sales to after-sales, KINGREAL STEEL SLITTER provides full professional support. Whether it is the design of the plan in the purchase stage, the support for equipment operation during the production process, or the technical service after installation and commissioning, KINGREAL STEEL SLITTER's staff will carefully connect to ensure that customers can feel the considerate service in every link.

KINGREAL STEEL SLITTER invites customers from all over the world to visit the KINGREAL STEEL SLITTER factory, experience the working status of the cut to length machine through actual operation, and further understand the performance and precision of the equipment. If you have any questions during the visit, KINGREAL STEEL SLITTER's engineering team will provide professional answers and support.

So far, KINGREAL STEEL SLITTER's shearing line has been successfully exported to India, Russia, Turkey, Egypt, the United Kingdom and other countries, and has established long-term cooperative relations with customers in more than 15 countries. In many successful cases, customers generally evaluate KINGREAL STEEL SLITTER's cut to length machine for its high quality, strong durability and easy operation, which greatly improves their production efficiency.

KINGREAL STEEL SLITTER knows that quality is the core element of whether the equipment can be recognized by the market, so KINGREAL STEEL SLITTER strictly controls quality in every link. The following are several key measures for KINGREAL STEEL SLITTER to ensure the quality of the shearing line:

1. Raw material selection:

Before the cut to length line is manufactured, KINGREAL STEEL SLITTER has extremely high requirements for the selection of raw materials.

KINGREAL STEEL SLITTER maintains a stable cooperative relationship with many long-term suppliers, but still conducts strict quality inspections on each batch of raw materials to ensure that its hardness, wear resistance and other performance indicators meet the requirements. Any unqualified raw materials will be returned and will never be used in production, ensuring the quality and stability of the final product.

|

|

2. Rigorous manufacturing:

During the manufacturing process of the cut to length line, KINGREAL STEEL SLITTER's engineers strictly follow each process standard to ensure that each component meets the precision manufacturing requirements.

Even a small screw is required to fit perfectly with the rest of the machine, with an accuracy error of no more than 0.1 mm. It is this attention to detail that ensures the stability and durability of KINGREAL STEEL SLITTER's cut to length line in long-term use.

|

|

3. Test the machine:

After the cut to length line is completed, KINGREAL STEEL SLITTER will conduct a series of rigorous tests to ensure that the performance of the equipment meets expectations.

The test process includes putting the machine into actual production, shearing plates of different materials (metal plates such as hot-dip galvanizing, aluminum plates, PPGI, etc.) and different thicknesses to ensure that the cutting effect meets the requirements. At the same time, the staff will measure the accuracy of the finished product and check whether the sheared plates are burr-free, scratch-free, and uniform in size. If any problems are found in the test, the technicians will immediately adjust and optimize to ensure that the equipment fully meets the needs of the customer.

Only after passing the test and confirming that the equipment meets the quality standards will the shearing line be officially delivered to the customer for use.

|

|

⭐With more than 20 years of industry experience, KINGREAL STEEL SLITTER has continuously innovated and optimized cut to length line products, and has won a good reputation in the global market with its high quality, stability and efficient production capacity. KINGREAL STEEL SLITTER firmly believes that with KINGREAL STEEL SLITTER's technical advantages, exquisite craftsmanship and professional services, it can help customers improve production efficiency and achieve more efficient metal processing.