Coil slitter is a kind of equipment specially used to cut metal coils (such as steel coils, stainless steel coils, aluminum coils, etc.) into multiple narrower strips along a certain width. It is widely used in industries such as steel, home appliances, automobiles, machinery manufacturing, construction and packaging. Especially in the production process where large coils of metal materials need to be processed into small coils or small strips, coil slitting lines play a vital role.

The working principle of the coil slitter is mainly to cut the metal coils longitudinally through the slitting cutter and divide them into several strip products according to the width required by the customer. The equipment usually consists of a feeding system, a slitting device, a receiving system, a tension control system, a guide system and other parts. The feeding system feeds the metal coils into the coil slitting line, and after tension control and guide adjustment, ensures that the material will not deviate or fluctuate during the slitting process. Then, after the metal coils are cut by the slitting cutter, they are cut into multiple small coils or strips according to the predetermined width, and finally the strips after slitting are rolled into coils through the receiving system.

With more than 20 years of industry experience, KINGREAL STEEL SLITTER has exported its high-quality coil slitter equipment to more than 20 countries and regions around the world, including India, Russia, the Philippines, Saudi Arabia, Vietnam, etc.

Every communication and cooperation with customers not only allows KINGREAL STEEL SLITTER to have a deep understanding of the differences in demand for coil slitting lines in different countries, but also prompts us to continuously optimize our products and services to meet the diverse needs of global customers. Whether in terms of equipment performance, customized functions, or after-sales service, KINGREAL STEEL SLITTER always adheres to the principle of providing customers with the best experience, and has therefore won high praise from customers in the international market.

KINGREAL STEEL SLITTER focuses on the customer's all-round experience. From pre-sales to sales and after-sales, every link is tracked by a dedicated person throughout the process to ensure that every customer's needs can be responded to and handled in a timely manner.

Whether it is equipment selection, technical support, or equipment installation, commissioning and post-maintenance, KINGREAL STEEL SLITTER helps customers achieve production goals through efficient communication and service, and any problems encountered during use can be quickly resolved.

In order to demonstrate KINGREAL STEEL SLITTER's professional capabilities and service quality, the following will share a case of cooperation with a Bangladeshi customer - the customization process of a 230m/min high-speed coil slitting line.

This Bangladeshi customer contacted us after learning about KINGREAL STEEL SLITTER's coil slitting line products through the KINGREAL STEEL SLITTER official website. The customer put forward the demand for the coil slitter. KINGREAL STEEL SLITTER staff introduced the operation process, working principle and related technical indicators of the coil slitting line in detail through online communication, and sent relevant videos to show the performance of the coil slitter in actual production, especially the advantages in processing narrow strip precision. At the same time, in order to better understand the needs of customers, KINGREAL STEEL SLITTER engineers conducted research on the Bangladesh market to understand the specific needs and technical requirements of the market for coil slitting lines, which laid the foundation for subsequent communication and the formulation of customized solutions.

|

|

After preliminary communication, the Bangladeshi customer showed great interest in our high-speed coil slitter and decided to learn more about the product.

In order to let customers have a more comprehensive understanding of KINGREAL STEEL SLITTER’s coil slitting line, KINGREAL STEEL SLITTER invited Bangladeshi customers to visit the factory for a field visit. Through this factory visit, customers can intuitively feel the manufacturing process, equipment quality and work efficiency of KINGREAL STEEL SLITTER's coil slitting line.

During the visit, KINGREAL STEEL SLITTER staff introduced the key components of the high-speed coil slitter in detail, and especially emphasized KINGREAL STEEL SLITTER's strict standards for raw material selection. KINGREAL STEEL SLITTER has conducted rigorous tests on the hardness, wear resistance and other properties of the raw materials to ensure that each coil slitting line can maintain excellent performance during long-term operation.

Bangladeshi customers highly recognized KINGREAL STEEL SLITTER's meticulous manufacturing process and raised some technical questions, such as the maximum production speed of the coil slitting machine and the range of metal thickness that can be processed. KINGREAL STEEL SLITTER staff provided detailed answers to these questions, especially about the production capacity of the high-speed coil slitting line - its maximum production speed can reach 230m/min, and it can process metal raw materials with a thickness range of 0.4 to 5mm. This flexible adaptability also impressed the customer.

Through field visits and detailed answers, Bangladeshi customers have a deeper understanding of KINGREAL STEEL SLITTER's professionalism and strength, and have preliminarily determined their intention to cooperate.

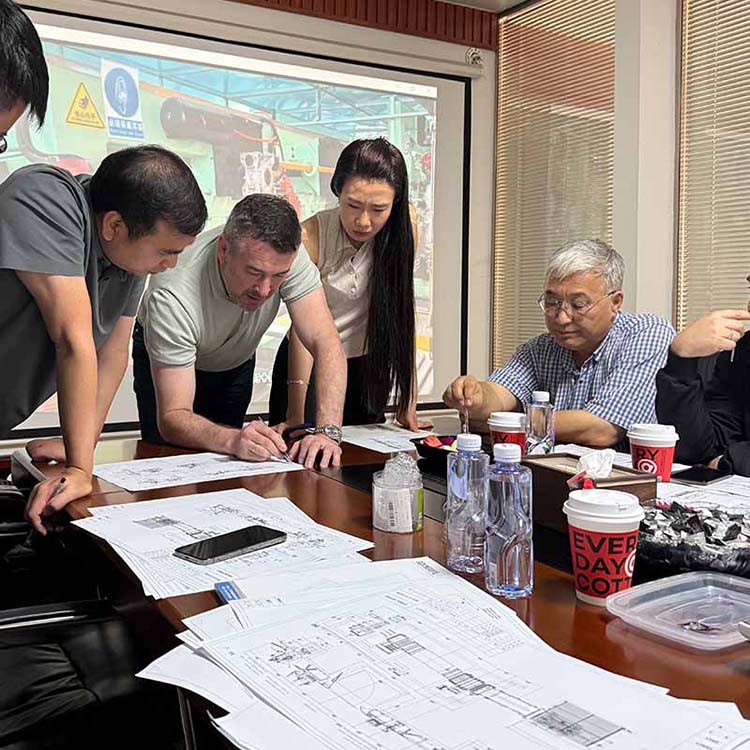

After visiting the production workshop of the coil slitting line, KINGREAL STEEL SLITTER staff invited customers to the conference room for further discussion. In this session, KINGREAL STEEL SLITTER engineers had in-depth communication with Bangladeshi customers and learned about the customer's production needs in detail, including monthly production time, types of metal materials to be processed, and output requirements. Through a comprehensive understanding of customer needs, KINGREAL STEEL SLITTER engineers tailored a high-speed coil slitting line solution for the customer that meets its production requirements.

|

|

Finally, the customized solution is as follows:

⭐ Metal coil thickness: 0.4-5mm

⭐ Metal coil material: GI steel, cold-rolled steel, PPGI

⭐ Metal coil width: 1650mm

⭐ Slitting speed: 230m/min

The design of this solution fully considers the production needs of Bangladeshi customers and provides an efficient and stable slitting solution for their production line.