KINGREAL STEEL SLITTER is one of the most professional coil process equipment manufacturer and supplier in China. KINGREAL can provide copper coil slitting machine, which can precise slitting the copper coil to the same width. Welcome to ask for a quotation.

Video About Copper Slitting Machine

Video About Copper Slitting Machine

Description Of Copper Coil Slitting Machine

Description Of Copper Coil Slitting Machine

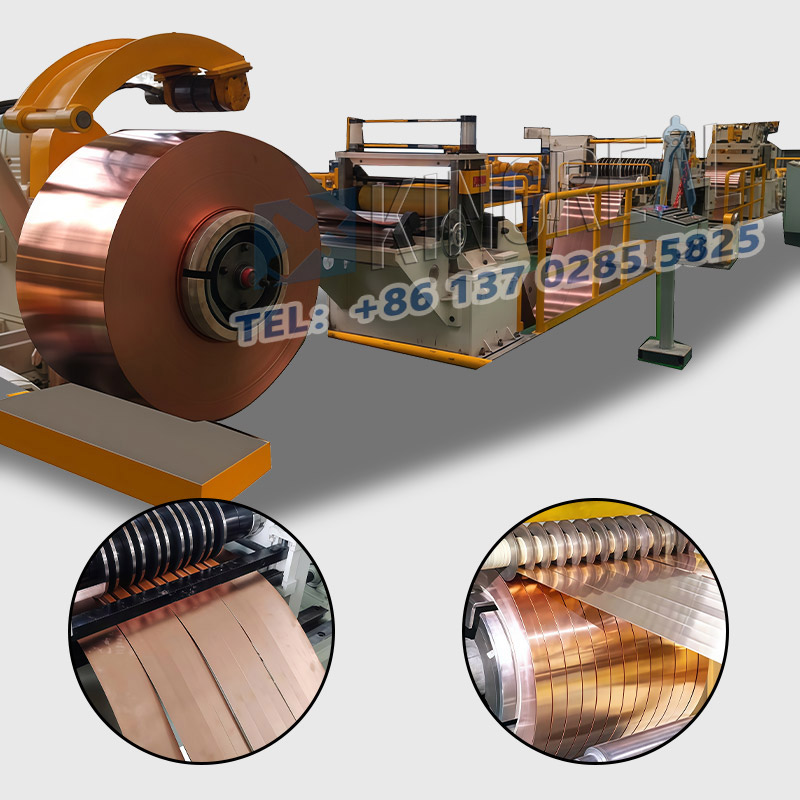

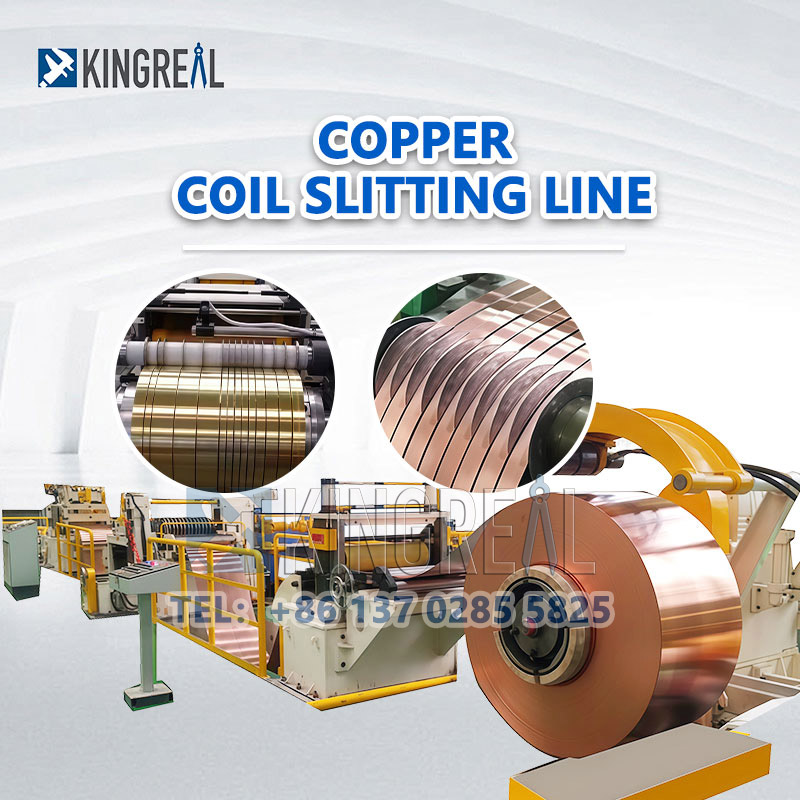

KINGREAL STEEL SLITTER copper coil slitting machine is design to slitting the copper coil. The Production of copper slitting line is a continuous slitting production line in which the wide coil is opened by the decoiler, the coil is cut into a specific width by the slitting machine, and finally wound into several coils by the rewinder.

KINGREAL STEEL SLITTER has a complete production workshop and professional engineers to ensure the high quality of all production parts of copper strip slitting machine, which error of its production can be controlled within 3mm.

(Other thickness material slitting can be customized)

Copper Coil Slitting Machine Working Process

Copper Coil Slitting Machine Working Process

Loading Coil Car -- Hydraulic Decoiler -- Pinch Roller -- Looping Bridge -- Slitting Machine -- Looping Bridge -- Tension -- Rewinder

Copper Coil Slitting Machine Reference Date

Copper Coil Slitting Machine Reference Date

|

Machine Type |

Coil Slitting Line |

|

Coil Material |

Copper (other can be customized |

|

Coil Out Diameter |

Φ1600mm |

|

CoilInner Diameter |

Φ500mm |

|

Coil Weight |

20 T |

|

Max Tensile Strength |

Consider ultimate strength 80kg/mm2 |

|

MaxYieldStrength |

60kg/mm2 |

|

PlateThickness |

0.1mm-1.2mm |

|

BoardPair |

310mm-680mm |

Feature Of Copper Coil Slitting Machine

Feature Of Copper Coil Slitting Machine

The guide device is mainly composed of left and right sliders, worm gears and worms.Using the slider structure can greatly reduce the gap of the guide mechanism, so that the axial movement of the main shaft is less than 0.1mm, and the radial gap is also less than 0.03mm.

The stability of the spindle is improved, and the shearing accuracy is guaranteed.

The transmission part consists of AC motor, gearbox, universal coupling, etc. Low noise, stable transmission, high efficiency and long life.

The lubrication system includes thin oil lubrication system and dry oil lubrication system, and the reduction box adopts its own thin oil lubrication.

The upper and lower cutter shafts are respectively supported in the two bushings on the movable support of the frame and the fixed support, and the cutting amount of the blade can be adjusted by adjusting the worm gear and worm to change the distance between the cutter shafts.

Advantage Of Copper Coil Slitting Machine

Advantage Of Copper Coil Slitting Machine

√ High automation level, which can increase productivity, reduce operating costs

√ Separate coil preparation system

√ Customized design, KINGREAL engineers will design special machine drawings according to customer needs

Application Of Copper Strips Coil

Application Of Copper Strips Coil

Steel factory

Transformer

Electrical motor

Electrical equipment

Car part

Building materials

Door

Packaging industries

FAQ

FAQ

With more than 20 years experience in manufacturing the machines and KINGREAL STEEL SLITTER are a manufacturer. So we can provide the strong and powerful service before and after sales.

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

We will pick you up at the station or airport.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

Yes, KINGREAL STEEL SLITTER are a manufacturer. We have a factory and our own technical team, feel free to visit us.